1. Introduction

The newly developed OWLA steel gravity valveless filter (patent number: ZL 2016 22 0893365.6) is widely used in surface water purification, iron and manganese removal from groundwater, bypass filtration of circulating water, suspended impurities removal from production waste water, subsequent filtration of organic waste water after biochemical treatment and secondary sedimentation tank treatment, and indoor swimming treatment. It is an ideal equipment for water treatment. The equipment consists of water intake system, water filtration system, filter media, supporting layer and support, water distribution system, backwash system, drainage system and so on.

2. Workflow

At the beginning of the filtration, there is a level difference between the siphon riser and flushing tank (the initial head loss). As the filtration time goes on, the suspended matter intercepted by the filter layer increases, the resistance increases, the head loss increases, and the water level in the siphon riser rises accordingly. The original air in the pipe is compressed, and part of the air enters the atmosphere through the water seal at the outlet of the siphon downcomer.

With the increase of filter resistance, the water level in the siphon riser rises continuously. When the water level rises to the orifice of the siphon riser, the water flows downstream from the auxiliary pipe, and the air in the siphon riser is continuously pumped out by the suction pipe due to the vacuum formed by the downward flow and the suction action of the water flow in the pipe. Causing rise of water level in siphon riser. At the same time, the siphon downcomer suck the water from the drainage well to a certain height. When the water level in the riser passes over the top of the siphon and falls, the falling water and the rising water column in the downcomer flush out of the downcomer and take away all the residual air in the pipe, forming a continuous siphon flow. At this time, because of the sudden drop of pressure in the upper part of the filter layer, the water in the tank enters the siphon in the opposite direction of filtration, and the filter layer is backwashed. The flushing wastewater is drained into the sewer by the drainage well.

During the washing process, the water level in the water tank gradually drops. When the water level drops to the siphon destroying bucket, the water in the bucket is sucked up, the pipe mouth is connected with the atmosphere, the siphon is destroyed, the flushing is finished, and the filtration starts again.

OWLA gravity valveless filter will automatically backwash the filter layer using siphon principle, especially for decentralized water supply projects lacking professionals.

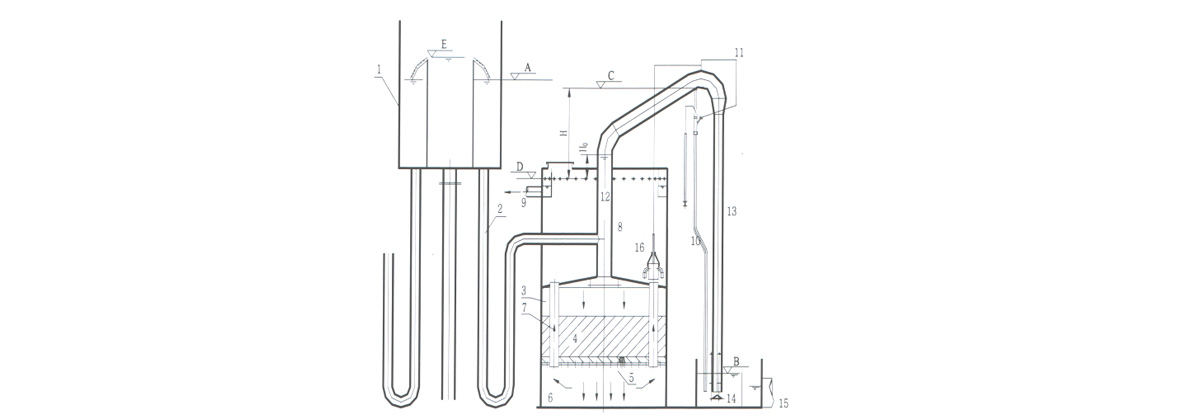

working map

1、Inlet tank |

2、Inner inlet | 3、Dirty water area | 4、Filter room | 5、Filter plate | 6、Water collection | 7、Connection | 8、Clean water tan |

9、Outlet | 10、Siphon auxiliary pipe | 11、Gas vent | 12、Siphon riser | 13、Siphon downcomer | 14、Water seal tank | 15、Drainage | 16、Siphon destruction bucket |

17、Forced flushing pipe | |||||||

A:Water level of inlet tank | B:Liquid level of drainage box | C:Level of Siphon sucking auxiliary pipe mouth | D:Maximum outlet water level | E:Level of Distribution weir | H:Final allowable head loss |

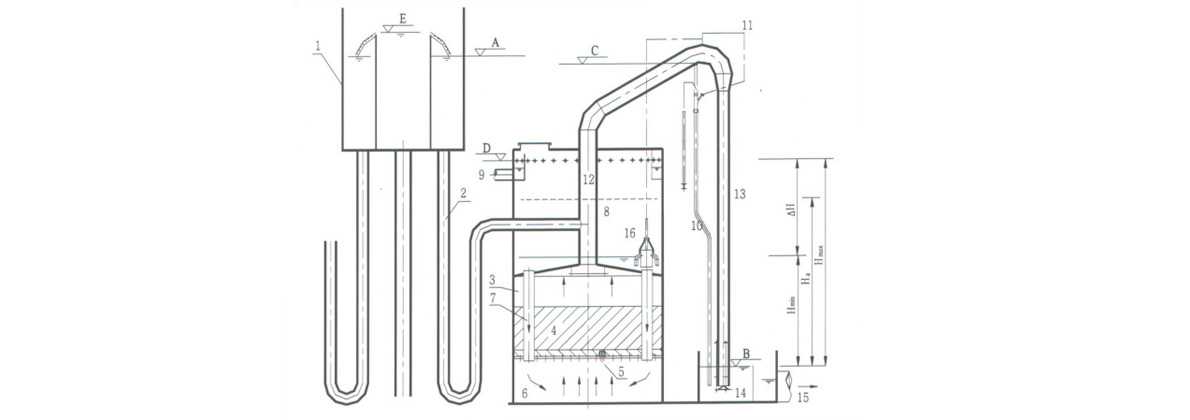

working map

1、Inlet tank | 2、Inner inlet | 3、Dirty water area | 4、滤料 | 5、Filter plate | 6、Water collection | 7、Connection | 8、Clean water tan |

9、Outlet | 10、Siphon auxiliary pipe | 11、Forced backwash pipe | 12、Siphon riser | 13、Siphon downcomer | 14、Drain tank | 15、Drainage | 16、Siphon destruction bucket |

17、Seal weir | 18、Forced flushing pipe | HmaxFlushing head | HminFlushing head | HaFlushing head | △HEfficiency depth of clean tank |